Express Workflow

Express Workflow

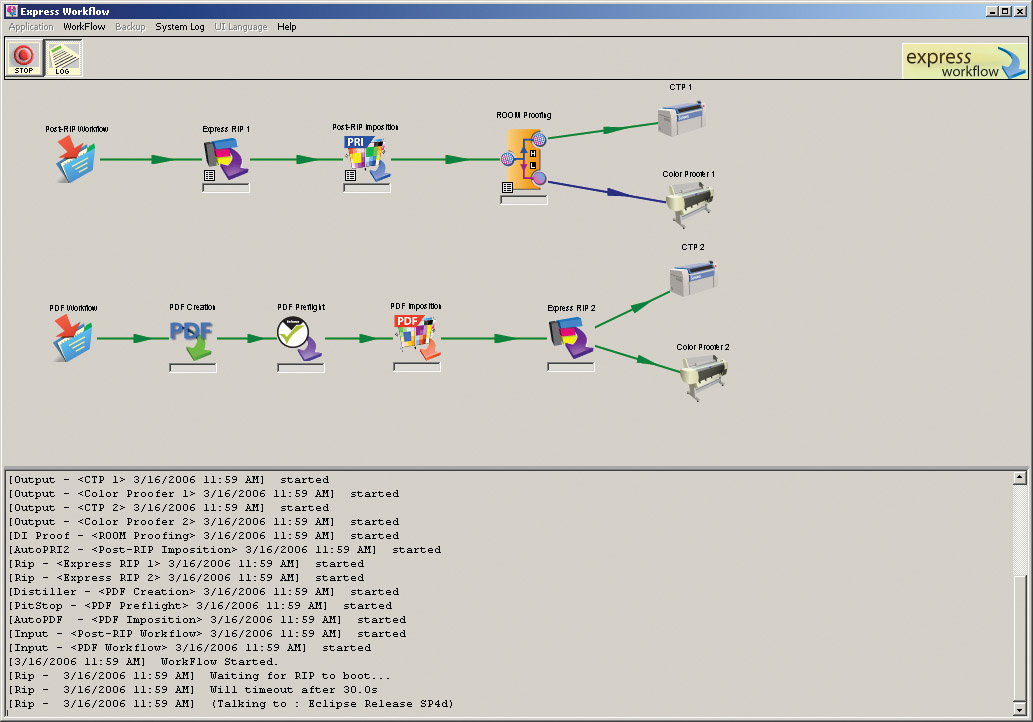

Express WorkFlow is designed to provide reliability, scalability, and efficiency for evolving prepress industry requirements. It combines functional integration with user-focused operation, supporting seamless process integration and data transfer throughout the prepress workflow. The latest version includes JDF support at all production stages, such as ripping preferences, imposition methods, InkScript values, folding instructions, binding, and guillotine settings. Additional improvements have been made to workflow features and overall system performance.

JDF Support

Express WorkFlow supports JDF files, allowing job receipt in JDF format from MIS systems. Processing instructions embedded in these files configure workflow modules during job processing. The system also generates JDF files for presses, folding, and cutting equipment.

Auto-Versioning Tool

Automated versioning is available for multi-lingual jobs, supporting both separate files per language or a consolidated PDF. Express WorkFlow merges language separations with black channels for CTP output or reconstructs full separations for proofing.

Press integration

Express Workflow has now been integrated with the Compose InkScriptOptimiser, an application that allows users to standardise their RGB or CMYK images for printing. It will improve printability and reduce ink coverage while maintaining the original color and quality of the images on the prints.

InkScript for Ink Key Control

The Compose InkScript module supplies ink-key data in CIP3/4 or JDF formats, as well as ink-key charts in PDF or via Windows printer output. These functions help reduce press setup times and maintain consistency during print runs.

Enhanced Flatworking Productivity

The Plate Controller module optimises plate layout for label and standard jobs, providing front-and-back alignment and step-and-repeat functionalities for various project types.

Simplified Job Submission

Remote Job Manager allows job submission and approval on both Mac OS X and Windows PC platforms. Users can utilise workflow templates for rapid submission or configure individual job and workflow settings as needed.

Remote Job Tracking

Job progress can be monitored remotely on Mac OS X and Windows PCs using filters such as usernames, time periods, or job names.

Configure While Print

Express WorkFlow 3 permits new settings creation during active workflows, allowing configuration adjustments without pausing operations.

Load Balancing for Productivity

The Remote Load Balance module distributes jobs across multiple modules—including RIP or DI Proof—for optimal throughput and resource utilization.

Distributed Processing

Remote Service support distributes workflow tasks across multiple computers, reducing processing bottlenecks. Additional Express RIP modules can be added to manage increased RIP processing demand.

Fault Tolerance

Web Service and Remote Load Balance modules reroute jobs to operational modules if a failure occurs, supporting fault tolerance.

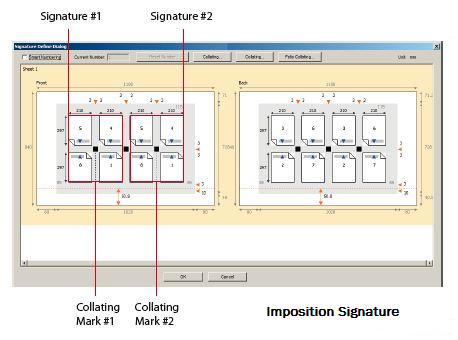

Advanced Imposition Solutions

PRI Station and PDF Imposition software provide imposition solutions for sheet-fed and web presses. Users can control signatures, page placement, gutter settings, margins, and flatwork for complex or multi-job impositions

Automated Imposition

Automated modules process 1-bit and PDF job files with minimal manual intervention, offering preview and verification before proofing or CTP output.

Modular Software Architecture

Express WorkFlow uses a modular design for reliability and scalability, centered around the Compose Express RIP—an optimized Harlequin RIP variant. It supports a range of input formats, including PostScript, PDF, EPS, PCL, and 1-bit TIFF, and is compatible with over 200 output devices.

Browser-based management enables remote monitoring, submission, and control. Modules are available for proofing, imposition (pre- and post-RIP), media optimization, and various imaging equipment drivers. Configuration is straightforward, with toolbar icons for arranging modules and efficient management for local and remote use.

Imposition modules integrate with the JDF module for managing page placement and generating detailed instructions for folding, creasing, trimming, and cutting. JDF-enabled tracking allows searching by job name, user, timeframe, status, and history. Express WorkFlow supports inkzone profiles and is compatible with JDF-enabled Harlequin ScriptWorks RIP.

One-click configuration

The imposition modules PRI Station, PDF Imposition and Plate Controller use the Express WorkFlow’s JDF module to manipulate page placement and generate the appropriate folding, creasing, trimming and cutting instructions. Job tracking using JDF tickets allow users to search for jobs by job name, user name, and time period and job information, job status, and history can be monitored.

Express WorkFlow takes advantage of the JDF format to support inkzone profiles, folding, creasing, trimming and cutting. It also fully supports the JDF-enabled Harlequin ScriptWorks RIP to provide easy and flexible RIP configuration.

JDF automation for greater control

End-to-end PDF workflow

Express WorkFlow utilizes a PDF-centric approach for reliable RIP processing, client interaction, and security. Incoming PostScript files convert to PDF through Adobe Distiller, with preflighting handled by EnfocusPitStop Pro. Certified PDFs are rasterized by Express RIP for high-resolution separations or composite soft proofs.

Raster file roaming in full or reduced size

Support multiple fileformats

Express WorkFlow processes formats such as PostScript, PDF, EPS, PCL, and 1-bit TIFF. Jobs can be submitted via hot folders or web applications. Spool folders manage single-file jobs, and the Composer Module handles multi-file deliveries. Raster Import supports halftone file formats like 1-bit TIFF, NetFlow Raster, and Harlequin PageBuffer.

Browser-Based Management and Tracking

Accessible from a browser, the database maintains job information to support local and remote processes. Users can monitor workflows and access job managers from the interface.

Extensive Output Device Support

Compose has developed digital color and imagesetting solutions, tuning Express RIP drivers for a variety of output devices, including plotters, printers, imagesetters, and platesetters. There are more than 12,000 Express RIP installations worldwide.

Flexible Soft Proof Delivery

The Internet module generates composite PDF files for soft proofing, supporting client approval via email or FTP. Automation facilitates client reviews and expedites feedback.

Remote Printing Options

Express WorkFlow delivers job files directly to designated locations using the internet. Raster PDFs are generated for download and precise proof production.

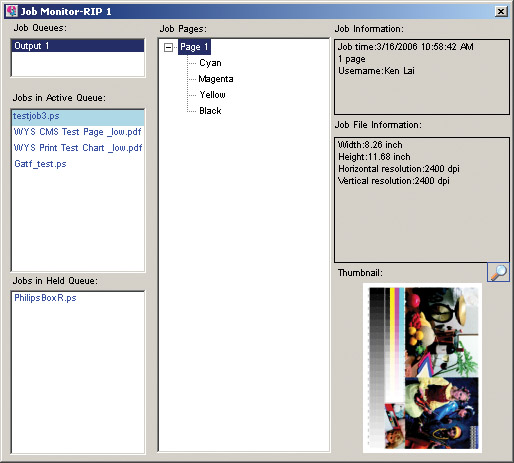

Output Control with Raster PrintStation

RasterPrintStation manages jobs in the output queue, supporting TIFF, NetFlow Raster, or Harlequin PGB formats. Users can configure devices, preview, hold, release, redirect, or reorder jobs. Advanced options include cropping, tiling, and step-and-repeat.

Ink Usage Optimization

The InkScript module analyzes color profiles and generates CIP3 PPF files to manage ink levels. InkDuct accepts 1-bit TIFF files for effective press ink management.

Supported Modules and Applications

- Imposition

- Express RIP

- PlateController